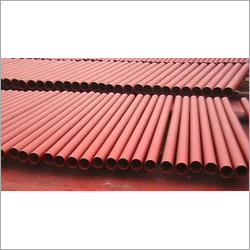

Cast Iron Spun Pipes

Price 1100 INR/ Meter

Cast Iron Spun Pipes Specification

- Surface Finish

- Manual Polish

- Product Type

- Cast Iron Spun Pipes

- Material

- Cast Iron

- Type

- Casted

- Shape

- Round

- Alloy or Not

- Alloy

- Hardness

- Yes

- Warranty

- 1 year

Cast Iron Spun Pipes Trade Information

- Minimum Order Quantity

- 600 Meter

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About Cast Iron Spun Pipes

We are a distinguished enterprise engaged in manufacturing and supplying of supreme quality Cast Iron Spun Pipes. Quality tested raw material like iron alloy, sourced from certified dealers are used in the processing of these range at our advanced infrastructural plant. Well known for its efficiency and durability these pipes reduces the time coverage by effectively controlling the pressure and heavy blow. Furthermore, these are easy to instal, corrosion proof and other more.

Features of cast iron socket & spigot pipes are:

- Compliance to is-1536

- High quality hard chrome plated parts and aluminum alloy die set with texture

- High quality solenoid and hydraulics

- Compact design structure for more work space

- Minimum power consumption

- Powerful pipe ejection system with the help of sockets

Superior Durability and Craftsmanship

Our Cast Iron Spun Pipes are engineered with alloy-enhanced cast iron, delivering increased hardness and resilience. The manual polish surface enhances both appearance and durability, making them well-suited for long-term infrastructure projects and high-stress environments.

Trusted Manufacturing in India

Manufactured and supplied in India, these pipes benefit from stringent quality controls and advanced casting processes. With a 1-year warranty, customers receive full support and assurance in the pipes performance and dependability in critical installations.

FAQs of Cast Iron Spun Pipes:

Q: How are cast iron spun pipes manufactured?

A: Cast iron spun pipes are produced using a centrifugal casting method, where molten alloy cast iron is spun at high speeds inside a mould. This process ensures uniform density, enhanced hardness, and a smooth interior surface, making each pipe reliable and durable.Q: What are the benefits of choosing round, alloy cast iron pipes?

A: Round, alloy cast iron pipes offer superior strength and corrosion resistance. Their shape provides even pressure distribution, and the alloy composition increases hardness and longevity, making them ideal for heavy-duty infrastructure and industrial use.Q: When should I use manually polished cast iron spun pipes?

A: These pipes are recommended when you require an aesthetic finish combined with durability. The manual polish not only improves appearance but also smoothens the surface, reducing friction and improving flow in water, sewage, or drainage applications.Q: Where are these cast iron spun pipes typically used?

A: They are widely applied in municipal water supply systems, drainage, sewage lines, and various industrial installations that demand robust, long-lasting piping solutions capable of withstanding high pressures and harsh conditions.Q: What is the process for installing these pipes?

A: The installation process involves site preparation, alignment of the round pipes, secure jointing (commonly using gaskets or sleeves), and thorough quality checks. Professional installation ensures leak-proof and reliable operation throughout the systems service life.Q: How does the 1-year warranty benefit customers?

A: The 1-year warranty provides peace of mind by guaranteeing that any manufacturing defects or performance issues within the period will be promptly addressed by the manufacturer or supplier, ensuring reliability and support after purchase.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Pipes Category

Cast Iron Spigot Pipes

Price 1350 INR / Meter

Minimum Order Quantity : 500

Material : Cast Iron

Shape : Round

Color : Black or Grey

Length : 3 m to 5.5 m

Cast Iron Soil Drainage Pipes

Price 1600 INR / Number

Minimum Order Quantity : 500

Material : Cast Iron

Shape : Round

Color : Black

Length : 2.5 m to 3 m

Cast Iron Double Flanged Pipes

Price 1450 INR / Meter

Minimum Order Quantity : 5 TON Meters

Material : Cast Iron

Shape : Round

Color : BLACK

Length : 5 Meter (m)

Puddle Pipe

Price 80 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material : Stainless Steel

Shape : Round

Color : BLACK

Length : 600 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS